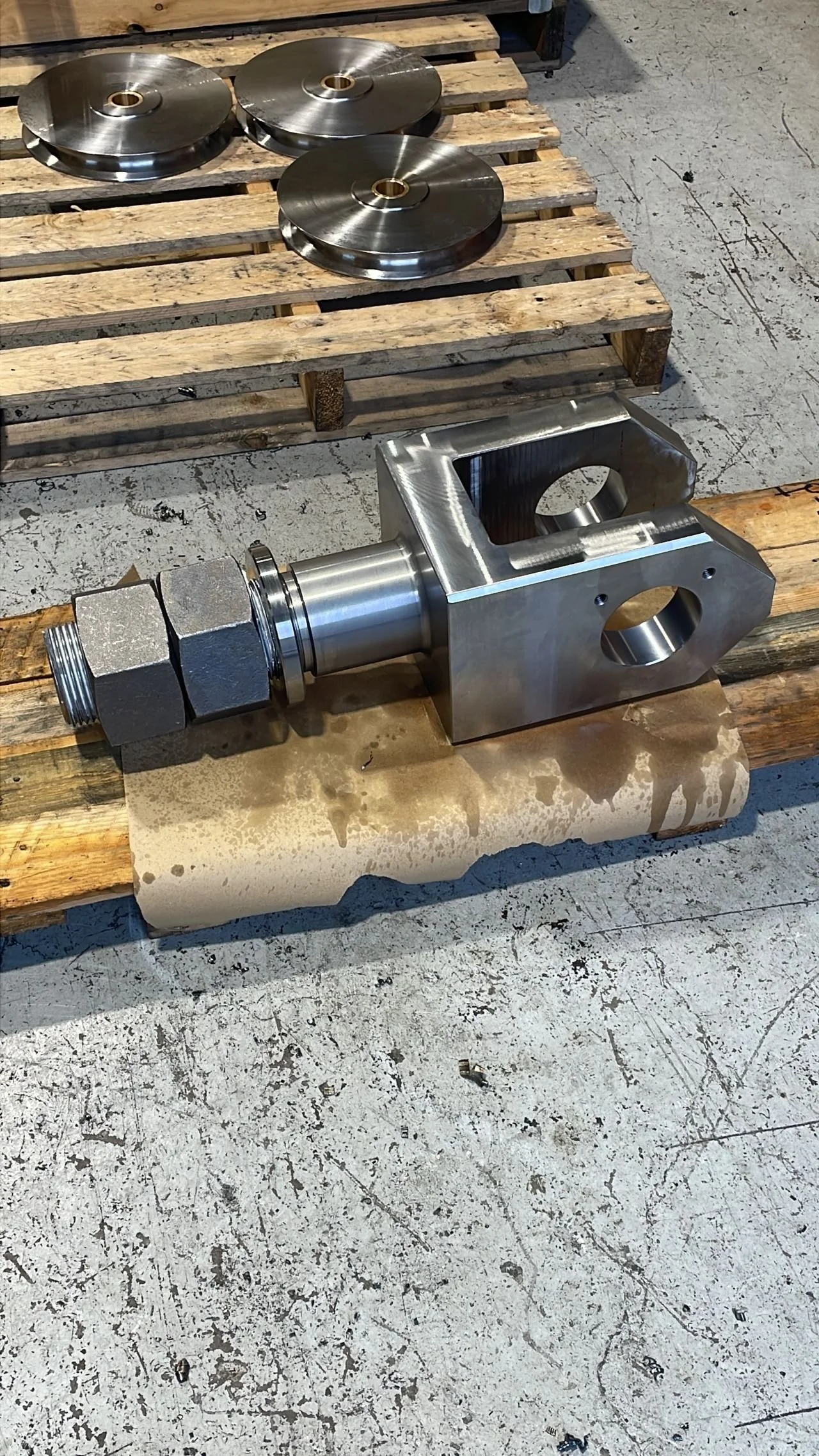

Comprehensive precision engineering and machine shop

Unanderra based jobbing machine shop, with a varied range of services to handle your engineering requirments.

Our fleet of CNC and manual machine tools has been designed to offer the most well-rounded machine shop service we can provide.

Our approach

Collaborative and engaged.

We enjoy providing a multi-faceted engineering service, able to respond to the needs of many industries, local, nationwide and globally.

Offering CNC and manual machining, with the ability create one off, custom components unable to be sourced from an OEM, to executing large production runs, and management of stock for custom machined components.

We are well positioned to perform all aspects of repair and reclaim work, manufacturing new parts, mechanical overhaul and maintenance of industrial equipment across industries such as Steelmaking, Mining, Sugar, Agricultural, Automotive and Paper manufacturing.

Working from customer supplied, original drawings, or collaborating to solve an issue via reverse engineering, we are willing to tackle any engineering challenge and are excited to become involved in your project.

CNC Machining

Okuma MX55VB - 3 axis Vertical M/C Centre.

Hartford LG500 - 4 axis Vertical M/C Centre

Okuma LB300-MY C and Y axis Turning Centre

Victor V Turn 36 2 axis turning centre

Hyundai Kia SKT28LM C Axis Turning Centre

Nakamura TMC20 2 axis Turning Centre

Our Equipment

Manual Machine Tools

4 Manual Lathes up to 800mm swing and 4000mm centres.

3 Manual Mills up to 1700mm Table.

2 Surface grinders up to 600mm table.

250mm x 750mm Cylindrical Grinder.

6” stroke slotter for smaller keyways and splines.

Fromag KZH70 Keyseater for keyways up to 3” wide x 600mm long

Ancillary Equipment

TIG, MIG, Plasma, Saws, Oxy, Pressing and Pulling, Hoists, Jacks, and a huge range of heavy fitting tools allows us to think outside the box and accomplish almost any repair and maintenance challenge presented to us.

We work closely with external service providers to ensure we can complete the entire job, such as zinc plating, hard chroming, heat treatment, gear cutting and hobbing.

Where are we headed?

We are working to install EDM (Electro-Discharge-Machining) equipment.

We are working towards offering a spray welding service for reclaiming worn rotating equipment parts.

We welcome new opportunities to assist you with our engineering solutions, from all industries, and are always excited to work on new challenges with new and existing clients.

Get in Touch!

Our workshop is open 7am to 4:00pm Monday to Friday, and we welcome RFQ’s and enquiries via our contact form below.

All enquires welcomed.